The FOTRIC 340 Series represents a cutting-edge innovation in thermal camera technology, setting new benchmarks in accuracy and reliability. Powered by advanced components from renowned manufacturers like Lynred, Qualcomm, Xilinx, and TI, this infrared camera series is specifically designed for precise thermal detection, enabling early problem identification in buildings, electrical systems, and industrial environments. By detecting hot spots and temperature anomalies, these cameras help prevent costly repairs and ensure operational efficiency.

Versatile Applications of FOTRIC 340 Series Thermal Cameras

1. Building Inspections

Equipped with an industry-leading thermal sensitivity of 0.03°C, the FOTRIC 340 can detect even the smallest temperature variations. This allows for the early detection of issues like water leaks or heat loss in buildings. Additionally, the fusion imaging feature combines thermal and visual images, providing clear contrast to highlight potential problems.

For example, the thermal imaging capability can expose cold losses caused by thermal bridges in building materials. Moreover, a built-in laser range finder accurately measures distances and calculates area values using the ROI (Region of Interest) tool, ensuring more precise inspections.

A cold loss due to a material-related thermal bridge

2. Manufacturing Process Optimization

The thermal camera comes with a unique picture-in-picture (PIP) feature that allows users to overlay the thermal image on the visual image. This feature is particularly useful for inspecting complex machinery and equipment, enabling manufacturers to pinpoint heat anomalies in real time.

The FOTRIC 340 also includes a Speedy Intelligent Turbofocus system that offers various focus modes—thermal graphic contrast auto-focus, manual focus, and laser-assisted focus. This ensures crystal-clear thermal images, enhancing equipment maintenance and fault detection.

Heat anomaly of a refrigeration unit. The pump is shown in Picture-in-Picture mode

One single touch brings fast focus for crisp graphics in a LED lamp inspection

3. Solar Panel Maintenance

For solar panel inspections, the FOTRIC 340's high-resolution thermal imaging—up to 640x480—provides accurate thermal data from a distance. This helps identify defective panels showing as hot or cold spots, preventing inefficiencies in energy production. Such detailed infrared camera inspections can greatly improve solar panel maintenance, increasing overall energy output and system longevity.

Solar panel defects showing up as hot spots

4. Metallurgical Applications

Designed for harsh industrial environments, the FOTRIC 340 Series supports a wide temperature range from -20°C to 1550°C, making it ideal for steel plants, kilns, and other high-temperature settings. With this advanced thermal imaging capability, users can perform defect detection without disrupting industrial processes, ensuring operational safety and efficiency.

Converter and ladle in the steel mill

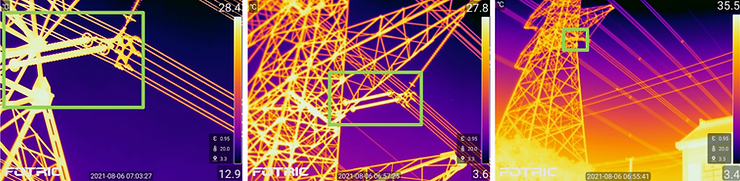

5. Electrical Utilities and Power Systems

The FOTRIC 340 Series enhances power system inspections with its Thermal White Balance (TWB) technology. This feature adjusts the thermal image to make cooler regions more visible, which is essential when working with equipment like transformers and AC contactors that operate across broad temperature ranges.

TWB off TWB on

In addition, the Fotric IRedge feature sharpens the target’s contours, improving the visibility of small yet critical components like distribution transformers. This advanced feature, along with optional lens ranges (7°, 12°, 25°, 44°), enables accurate thermal inspections for both distant targets (e.g., transmission towers) and closer inspections of equipment within substations.

Users can further analyze electrical equipment by utilizing the ROI measurement tools (spots, lines, boxes, and polygons), comparing the temperatures in different areas to detect potential malfunctions in components such as isolator switches or main transformers.

IRedge off IRedge on

Conclusion

The FOTRIC 340 Series thermal cameras are designed to meet the needs of multiple industries by providing unmatched thermal sensitivity, intelligent focus systems, and a versatile range of lens options. Whether you're inspecting buildings, maintaining manufacturing equipment, monitoring solar panels, or conducting industrial inspections, these infrared cameras provide the thermal data needed to prevent issues and ensure optimal performance.

The integration of advanced technologies such as TWB and IRedge further enhances the clarity and accuracy of thermal images, setting a new standard in the world of thermal imaging. By investing in the FOTRIC 340 Series, businesses can improve inspection efficiency, reduce downtime, and ultimately, save costs on repairs.

Explore more about its capabilities by visiting NovaTestPro.com or contacting info@NovaTestPro.com for any inquiries.